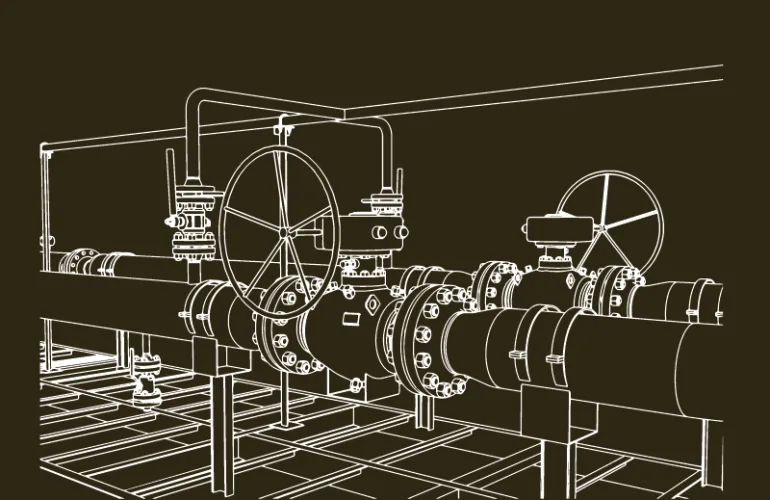

Fluid Conditioner

Fluid conditioners are essential systems used across industrial and commercial applications to control parameters such as temperature and pressure for fluids like air, water, oil, and fuel. By ensuring that fluids reach ideal conditions for a specific process or application, these systems play a vital role in maintaining efficiency and reliability. Their use is especially important in sectors such as aviation, aerospace, automotive, energy, and manufacturing, where operating fluids under precise conditions is critical for optimal system performance. Fluid conditioners support process optimization and contribute to energy savings by meeting these operational needs. A typical fluid conditioning system includes components such as heaters, coolers, pressure regulators, filters, and control units. Together, these elements allow precise adjustment of fluid temperature and pressure, improving overall system performance. The design and implementation of fluid conditioners are tailored according to the type of fluid being used, process requirements, and specific operational conditions. As a result, each project requires a customized solution. In systems operating under high pressure and temperature, proper material selection and robust control mechanisms are particularly important. Additionally, energy-efficient and environmentally conscious designs have become essential elements of modern industrial systems. Customized fluid conditioning solutions can be developed to match fluid type, process conditions, and performance requirements, providing high control precision with reduced energy consumption. By incorporating innovative technologies and adapting to diverse industrial needs, these systems enhance process efficiency while minimizing environmental impact.